導(dǎo)軌滑塊潤(rùn)滑脂的正確添加方法解析

來源:http://www.for-safe.com.cn/ 日期:2025-07-21 發(fā)布人:

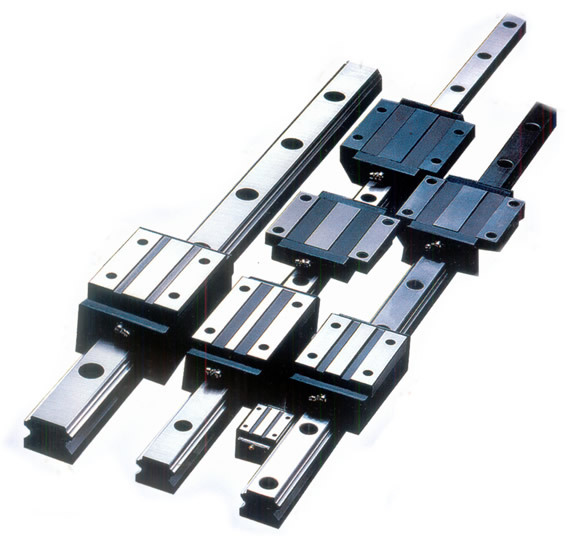

導(dǎo)軌滑塊作為機(jī)械傳動(dòng)中的關(guān)鍵部件,其順暢運(yùn)行離不開合理的潤(rùn)滑。潤(rùn)滑脂能減少滑塊與導(dǎo)軌之間的摩擦磨損,降低運(yùn)行噪音,延長(zhǎng)設(shè)備使用壽命。掌握正確的潤(rùn)滑脂添加方法,是保證導(dǎo)軌滑塊性能的重要環(huán)節(jié),需按照規(guī)范步驟操作,兼顧細(xì)節(jié)處理。

As a key component in mechanical transmission, the smooth operation of the guide rail slider relies on proper lubrication. Lubricating grease can reduce the friction and wear between the slider and the guide rail, lower the operating noise, and extend the service life of the equipment. Mastering the correct method of adding lubricating grease is an important step in ensuring the performance of the guide rail slider. It is necessary to follow the standardized steps and pay attention to details.

添加前的準(zhǔn)備工作直接影響潤(rùn)滑效果。要選擇適配的潤(rùn)滑脂,不同型號(hào)的導(dǎo)軌滑塊對(duì)潤(rùn)滑脂的粘度、耐溫性要求不同,需根據(jù)設(shè)備說明書的型號(hào)選購,避免因型號(hào)不符導(dǎo)致潤(rùn)滑不良或部件損壞。例如,高速運(yùn)行的導(dǎo)軌滑塊應(yīng)選用低粘度、流動(dòng)性好的潤(rùn)滑脂,而在高溫環(huán)境下工作的部件則需耐溫性強(qiáng)的潤(rùn)滑脂。其次,需清潔導(dǎo)軌和滑塊的潤(rùn)滑部位,用干凈的抹布或毛刷表面的油污、灰塵和金屬碎屑,若油污較厚,可先用煤油擦拭,待完全干燥后再進(jìn)行添加,防止雜質(zhì)混入潤(rùn)滑脂,加劇部件磨損。同時(shí),準(zhǔn)備好專用的加注工具,如黃油槍、注脂嘴等,確保工具清潔無雜質(zhì),避免污染潤(rùn)滑脂。

The preparation work before adding directly affects the lubrication effect. Firstly, it is necessary to choose the appropriate lubricating grease. Different models of guide rail sliders have different requirements for the viscosity and temperature resistance of the lubricating grease. It is necessary to select the recommended model according to the equipment manual to avoid poor lubrication or component damage caused by inconsistent models. For example, lubricating grease with low viscosity and good fluidity should be selected for high-speed running guide rail sliders, while lubricating grease with strong temperature resistance is required for components working in high-temperature environments. Secondly, it is necessary to clean the lubrication parts of the guide rail and slider, using a clean cloth or brush to remove surface oil, dust, and metal debris. If the oil is thick, it can be wiped with kerosene first, and then added after it is completely dry to prevent impurities from mixing into the lubricating grease and exacerbating component wear. At the same time, prepare specialized filling tools such as a grease gun, grease nozzle, etc., to ensure that the tools are clean and free of impurities, and to avoid contaminating the lubricating grease.

判斷添加時(shí)機(jī)是合理潤(rùn)滑的前提。導(dǎo)軌滑塊的潤(rùn)滑周期需根據(jù)使用頻率和工作環(huán)境確定,一般情況下,每天連續(xù)運(yùn)行 8 小時(shí)的設(shè)備,建議每?jī)芍芴砑右淮螡?rùn)滑脂;運(yùn)行頻率較低的設(shè)備,可每月添加一次。當(dāng)發(fā)現(xiàn)滑塊運(yùn)行時(shí)有異響、卡頓,或觀察到導(dǎo)軌表面潤(rùn)滑脂明顯減少、干涸時(shí),需及時(shí)補(bǔ)充。添加前需檢查潤(rùn)滑脂的狀態(tài),若潤(rùn)滑脂出現(xiàn)硬化、結(jié)塊或變色,說明已變質(zhì),需先將舊脂干凈,再添加新脂,避免新舊脂混合影響潤(rùn)滑效果。

Judging the timing of addition is a prerequisite for reasonable lubrication. The lubrication cycle of the guide rail slider needs to be determined according to the frequency of use and working environment. Generally, for equipment that runs continuously for 8 hours a day, it is recommended to add lubricating grease every two weeks; Devices with lower operating frequencies can be added once a month. When there is abnormal noise or jamming during the operation of the slider, or when the lubricating grease on the surface of the guide rail is significantly reduced or dried up, it is necessary to replenish it in a timely manner. Before adding, it is necessary to check the condition of the lubricating grease. If the grease hardens, clumps or changes color, it indicates that it has deteriorated. The old grease should be removed first, and then new grease should be added to avoid mixing old and new grease and affecting the lubrication effect.

具體添加過程需注重均勻與適量。對(duì)于帶有注脂嘴的導(dǎo)軌滑塊,將潤(rùn)滑脂裝入黃油槍,對(duì)準(zhǔn)注脂嘴緩慢擠壓,直有少量潤(rùn)滑脂從滑塊兩端溢出,表明內(nèi)部已充滿潤(rùn)滑脂。添加時(shí)需控制力度,避免因壓力過大導(dǎo)致潤(rùn)滑脂飛濺或部件變形。無注脂嘴的滑塊,可直接將潤(rùn)滑脂涂抹在導(dǎo)軌的滑動(dòng)面上,涂抹厚度以均勻覆蓋表面為宜(約 0.5-1 毫米),同時(shí)在滑塊的密封件內(nèi)側(cè)也需涂抹少量潤(rùn)滑脂,增強(qiáng)密封性,防止灰塵進(jìn)入。對(duì)于多滑塊組合的導(dǎo)軌,每個(gè)滑塊都需單獨(dú)添加,確保潤(rùn)滑均勻,避免因個(gè)別滑塊潤(rùn)滑不足導(dǎo)致整體運(yùn)行不暢。添加過程中,可手動(dòng)推動(dòng)滑塊往復(fù)移動(dòng)幾次,使?jié)櫥诨瑝K內(nèi)部充分分布,減少局部缺脂現(xiàn)象。

The specific addition process should pay attention to uniformity and moderation. For the guide rail slider with grease injection nozzle, insert lubricating grease into the grease gun, align with the grease injection nozzle and slowly squeeze until a small amount of lubricating grease overflows from both ends of the slider, indicating that the interior is filled with lubricating grease. When adding, the force should be controlled to avoid splashing of lubricating grease or deformation of components due to excessive pressure. For the slider without a grease nozzle, lubricating grease can be directly applied to the sliding surface of the guide rail, with a suitable thickness to evenly cover the surface (about 0.5-1 mm). At the same time, a small amount of lubricating grease should be applied to the inside of the sealing element of the slider to enhance sealing and prevent dust from entering. For guide rails with multiple slider combinations, each slider needs to be added separately to ensure uniform lubrication and avoid overall poor operation caused by insufficient lubrication of individual sliders. During the addition process, the slider can be manually pushed back and forth several times to fully distribute the lubricating grease inside the slider and reduce local grease shortage.

添加后的檢查與維護(hù)能保障潤(rùn)滑效果的持久性。添加完成后,啟動(dòng)設(shè)備空運(yùn)行 1-2 分鐘,觀察滑塊運(yùn)行是否順暢,有無異常噪音,若發(fā)現(xiàn)異常需立即停機(jī)檢查,排除潤(rùn)滑脂過多或部件卡滯的問題。運(yùn)行后再次清潔導(dǎo)軌表面溢出的多余潤(rùn)滑脂,防止吸附灰塵形成油泥。定期檢查潤(rùn)滑脂的消耗情況,結(jié)合設(shè)備運(yùn)行狀態(tài)調(diào)整添加周期,在粉塵較多、濕度較大的環(huán)境中,需縮短潤(rùn)滑周期,加強(qiáng)防護(hù)措施,如加裝防塵罩,減少雜質(zhì)對(duì)潤(rùn)滑部位的污染。長(zhǎng)期停用的設(shè)備,在啟用前需重新添加潤(rùn)滑脂,避免因潤(rùn)滑脂干涸導(dǎo)致啟動(dòng)時(shí)部件磨損。

The inspection and maintenance after addition can ensure the durability of the lubrication effect. After adding, start the device and run it idle for 1-2 minutes to observe if the slider runs smoothly and if there are any abnormal noises. If any abnormalities are found, stop the machine immediately for inspection to eliminate problems such as excessive lubricating grease or component jamming. After operation, clean the excess lubricating grease that overflows from the surface of the guide rail again to prevent the adsorption of dust and the formation of oil sludge. Regularly check the consumption of lubricating grease, adjust the addition cycle according to the operating status of the equipment. In environments with high dust and humidity, it is necessary to shorten the lubrication cycle and strengthen protective measures, such as installing dust covers to reduce the pollution of impurities on the lubrication parts. Equipment that has been out of use for a long time needs to be refilled with lubricating grease before use to avoid component wear during startup due to dry lubricating grease.

本文由導(dǎo)軌絲杠友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.for-safe.com.cn真誠(chéng)的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the guide screw For more information, please click: http://www.for-safe.com.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

導(dǎo)軌滑塊游隙怎么調(diào)?<>

導(dǎo)軌滑塊游隙怎么調(diào)?<> 導(dǎo)軌滑塊潤(rùn)滑脂的正確...<>

導(dǎo)軌滑塊潤(rùn)滑脂的正確...<> 導(dǎo)軌抗腐蝕材料有哪些...<>

導(dǎo)軌抗腐蝕材料有哪些...<> 絲杠制作過程解析<>

絲杠制作過程解析<> 絲杠動(dòng)態(tài)剛度怎么檢...<>

絲杠動(dòng)態(tài)剛度怎么檢...<>