導(dǎo)軌滑塊游隙怎么調(diào)?

來源:http://www.for-safe.com.cn/ 日期:2025-07-22 發(fā)布人:

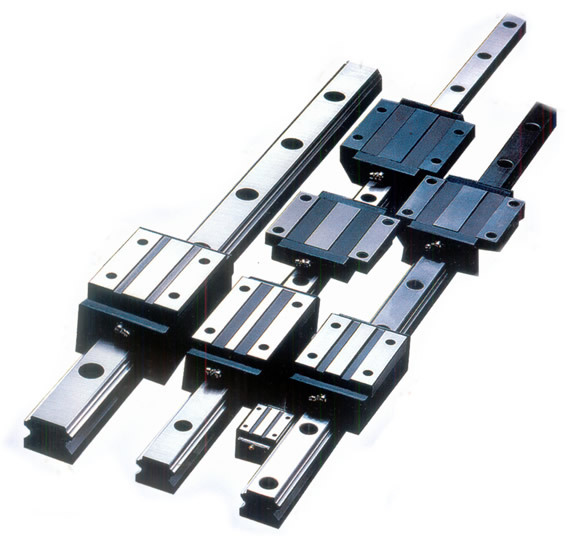

導(dǎo)軌滑塊作為機械運動系統(tǒng)中的關(guān)鍵部件,其游隙(即滑塊與導(dǎo)軌之間的間隙)直接影響設(shè)備運行的精度與穩(wěn)定性。游隙過大易導(dǎo)致運動晃動、定位不準(zhǔn),過小則會增加摩擦阻力,加速部件磨損。掌握科學(xué)的調(diào)節(jié)方法,既能保證機械系統(tǒng)的正常運轉(zhuǎn),又能延長導(dǎo)軌滑塊的使用壽命,適用于各類依賴導(dǎo)軌傳動的設(shè)備維護。

As a key component in mechanical motion systems, the clearance between the slider and the guide rail directly affects the accuracy and stability of equipment operation. Excessive clearance can easily lead to motion shaking and inaccurate positioning, while insufficient clearance can increase frictional resistance and accelerate component wear. Mastering scientific adjustment methods can ensure the normal operation of mechanical systems and extend the service life of guide rail sliders, making it suitable for maintenance of various equipment that relies on guide rail transmission.

調(diào)節(jié)前的檢查與準(zhǔn)備是確保調(diào)節(jié)效果的基礎(chǔ)。需判斷游隙是否需要調(diào)整:用手推動滑塊沿導(dǎo)軌移動,若感覺明顯松動或晃動,說明游隙過大;若移動阻力不均或有卡頓感,可能是游隙過小或存在異物。檢查時需清理導(dǎo)軌表面的灰塵、油污和金屬碎屑,可用毛刷蘸取清潔劑擦拭,再用干布擦干,避免雜質(zhì)影響調(diào)節(jié)精度。同時觀察滑塊與導(dǎo)軌的接觸情況,查看是否有局部磨損(如導(dǎo)軌表面出現(xiàn)劃痕、滑塊密封圈破損),若磨損嚴(yán)重需先更換部件再調(diào)節(jié)游隙,否則會導(dǎo)致調(diào)節(jié)后短期內(nèi)再次出現(xiàn)游隙異常。準(zhǔn)備好所需工具,包括內(nèi)六角扳手、塞尺、扭矩扳手等,不同型號的導(dǎo)軌滑塊對應(yīng)不同規(guī)格的工具,需提前確認適配性,避免因工具不當(dāng)損壞調(diào)節(jié)螺栓。

The inspection and preparation before adjustment are the basis for ensuring the effectiveness of the adjustment. Firstly, it is necessary to determine whether the clearance needs to be adjusted: push the slider along the guide rail with your hand, and if you feel obvious looseness or shaking, it indicates that the clearance is too large; If the resistance to movement is uneven or there is a sense of jamming, it may be due to insufficient clearance or the presence of foreign objects. During inspection, it is necessary to clean the dust, oil stains, and metal debris on the surface of the guide rail. A brush dipped in cleaning agent can be used to wipe it off, and then a dry cloth can be used to wipe it dry to avoid impurities affecting the adjustment accuracy. At the same time, observe the contact between the slider and the guide rail to see if there is any local wear (such as scratches on the surface of the guide rail or damage to the slider sealing ring). If the wear is severe, replace the component first and adjust the clearance, otherwise it will cause abnormal clearance to occur again in the short term after adjustment. Prepare the necessary tools, including hex wrenches, feeler gauges, torque wrenches, etc. Different models of guide rail sliders correspond to different specifications of tools. It is necessary to confirm the compatibility in advance to avoid damaging the adjusting bolts due to improper tools.

機械調(diào)節(jié)法是常用的游隙調(diào)節(jié)方式,適用于多數(shù)滾珠或滾柱導(dǎo)軌滑塊。該方法通過調(diào)整滑塊上的預(yù)緊螺栓改變游隙大小:順時針擰緊預(yù)緊螺栓時,螺栓推動滑塊內(nèi)部的楔形塊或偏心套,縮小滑塊與導(dǎo)軌之間的間隙;逆時針?biāo)砷_螺栓則會增大游隙。調(diào)節(jié)時需分次操作,每次轉(zhuǎn)動螺栓 1/4 圈后,推動滑塊感受阻力變化,并用塞尺測量實際間隙(通常游隙標(biāo)準(zhǔn)為 0.01-0.05 毫米,具體數(shù)值需參考設(shè)備說明書)。對于雙滑塊結(jié)構(gòu)的導(dǎo)軌,需兩側(cè)同步調(diào)節(jié),避免單側(cè)過緊導(dǎo)致導(dǎo)軌受力不均,產(chǎn)生彎曲變形。調(diào)節(jié)后需測試滑塊在全程范圍內(nèi)的移動順暢度,確保無明顯阻力突變,尤其注意導(dǎo)軌兩端的行程極限位置,防止因局部間隙不當(dāng)導(dǎo)致卡滯。

Mechanical adjustment method is the most commonly used clearance adjustment method, suitable for most ball or roller guide slider. This method changes the clearance size by adjusting the pre tightening bolt on the slider: when tightening the pre tightening bolt clockwise, the bolt pushes the wedge-shaped block or eccentric sleeve inside the slider, reducing the gap between the slider and the guide rail; Loosening the bolt counterclockwise will increase the clearance. When adjusting, it is necessary to operate in stages. After rotating the bolt 1/4 turn each time, push the slider to feel the change in resistance, and measure the actual clearance with a feeler gauge (usually the clearance standard is 0.01-0.05 millimeters, the specific value needs to refer to the equipment manual). For the double slider structure guide rail, it is necessary to adjust both sides synchronously to avoid uneven force distribution and bending deformation caused by one side being too tight. After adjustment, it is necessary to test the smoothness of the slider's movement throughout the entire range to ensure no significant resistance changes. Special attention should be paid to the travel limit positions at both ends of the guide rail to prevent jamming due to improper local clearance.

墊片調(diào)節(jié)法適用于需要精確控制游隙的場景,常用于高精度機床等設(shè)備。該方法通過增減滑塊與導(dǎo)軌之間的墊片厚度來調(diào)整游隙:當(dāng)游隙過大時,增加墊片(材質(zhì)多為銅或不銹鋼,厚度 0.02-0.1 毫米);游隙過小時,減少墊片。操作時需先松開滑塊固定螺栓,將滑塊從導(dǎo)軌上取下,根據(jù)測量的游隙值選擇合適厚度的墊片,放置在滑塊與導(dǎo)軌的接觸面上,再重新安裝固定。墊片需平整無毛刺,避免安裝后產(chǎn)生應(yīng)力集中,且墊片面積需與滑塊接觸面匹配,防止邊緣超出導(dǎo)致運動干涉。安裝完成后,需手動滑動滑塊檢查,確保全程阻力均勻,并用百分表測量導(dǎo)軌的平行度,保證調(diào)節(jié)后導(dǎo)軌的直線度誤差在允許范圍內(nèi)。

The gasket adjustment method is suitable for scenarios that require precise control of clearance and is commonly used in high-precision machine tools and other equipment. This method adjusts the clearance by increasing or decreasing the thickness of the shims between the slider and the guide rail: when the clearance is too large, add shims (mostly made of copper or stainless steel, with a thickness of 0.02-0.1 millimeters); If the clearance is too small, reduce the number of gaskets. When operating, first loosen the fixing bolt of the slider, remove the slider from the guide rail, select a suitable thickness gasket based on the measured clearance value, place it on the contact surface between the slider and the guide rail, and then reinstall and fix it. The gasket should be flat and free of burrs to avoid stress concentration after installation, and the gasket area should match the contact surface of the slider to prevent edge interference and motion interference. After installation, it is necessary to manually slide the slider to check for uniform resistance throughout the entire process, and use a dial gauge to measure the parallelism of the guide rail to ensure that the straightness error of the adjusted guide rail is within the allowable range.

液壓調(diào)節(jié)法多用于大型重載導(dǎo)軌系統(tǒng),通過液壓壓力控制滑塊與導(dǎo)軌的貼合度。該方法需借助設(shè)備自帶的液壓裝置,向滑塊內(nèi)部的油腔注入液壓油,利用油液壓力使滑塊膨脹,縮小與導(dǎo)軌的間隙。調(diào)節(jié)時需緩慢增加液壓壓力(通常控制在 0.5-2MPa),同時觀察滑塊的移動阻力,當(dāng)阻力達到預(yù)設(shè)值時停止加壓,關(guān)閉液壓閥保持壓力。液壓調(diào)節(jié)的優(yōu)勢在于可實現(xiàn)動態(tài)微調(diào),在設(shè)備運行過程中根據(jù)負載變化實時調(diào)整游隙,適合頻繁變載的工況(如起重機械的導(dǎo)軌系統(tǒng))。但需注意液壓系統(tǒng)的密封性,定期檢查油管接頭是否漏油,防止因壓力不足導(dǎo)致游隙異常。

Hydraulic adjustment method is commonly used in large heavy-duty guide rail systems, which controls the fit between the slider and the guide rail through hydraulic pressure. This method requires the use of the equipment's built-in hydraulic device to inject hydraulic oil into the oil chamber inside the slider, using hydraulic pressure to expand the slider and reduce the gap with the guide rail. When adjusting, it is necessary to slowly increase the hydraulic pressure (usually controlled at 0.5-2MPa), while observing the movement resistance of the slider. When the resistance reaches the preset value, stop pressurizing and close the hydraulic valve to maintain the pressure. The advantage of hydraulic regulation is that it can achieve dynamic fine-tuning, adjusting the clearance in real time according to load changes during equipment operation, suitable for frequent load changing conditions (such as the guide rail system of lifting machinery). However, it is important to pay attention to the sealing of the hydraulic system and regularly check for oil leakage at the oil pipe joints to prevent abnormal clearance caused by insufficient pressure.

本文由導(dǎo)軌絲杠友情奉獻.更多有關(guān)的知識請點擊:http://www.for-safe.com.cn真誠的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from the guide screw For more information, please click: http://www.for-safe.com.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 上一篇:導(dǎo)軌滑塊潤滑脂的正確添加方法解析

- 下一篇:

導(dǎo)軌滑塊游隙怎么調(diào)?<>

導(dǎo)軌滑塊游隙怎么調(diào)?<> 導(dǎo)軌滑塊潤滑脂的正確...<>

導(dǎo)軌滑塊潤滑脂的正確...<> 導(dǎo)軌抗腐蝕材料有哪些...<>

導(dǎo)軌抗腐蝕材料有哪些...<> 絲杠制作過程解析<>

絲杠制作過程解析<> 絲杠動態(tài)剛度怎么檢...<>

絲杠動態(tài)剛度怎么檢...<>